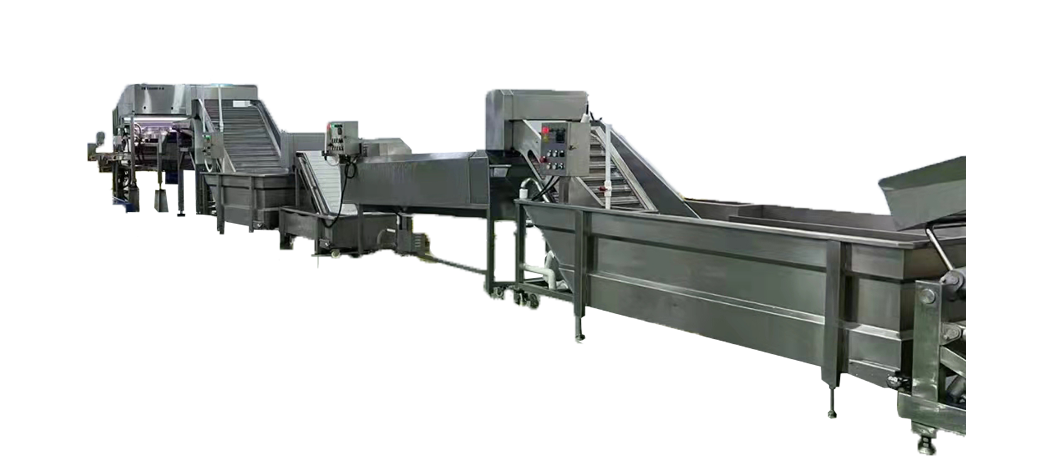

Automatic Shrimp Deheading Processing Line

Automatic Shrimp Deheading Processing Line Typical Applications

- Shrimp Processing Plants – Large-scale deheading and preparation for export markets

- Seafood Export Factories – Processing white shrimp, tiger shrimp, and prawns for Europe, USA, Japan

- Cold-Chain Production – Deheaded shrimp prepared for freezing, IQF processing, and long-distance export

- Integrated Shrimp Processing Lines – Works with peeling, deveining, freezing, and packaging equipment

An Automatic Shrimp Deheading Processing Line is a high-efficiency seafood processing system that automates the removal of shrimp heads. Unlike manual deheading, which requires hundreds of workers and leads to inconsistent results, this automated solution ensures high precision, minimal meat loss, and stable output at scale.

It is not just a single machine, but a complete shrimp processing system that integrates feeding, alignment, deheading, cleaning, and transfer to the next stage. Many seafood processors also refer to it as a shrimp processing line or shrimp processing equipment, since it serves as the first stage of a full shrimp processing workflow.

Why It Matters

- Labor Saving – One line can replace dozens of workers, cutting labor costs by up to 70%.

- Export Quality – Ensures consistent size and clean deheading, meeting EU/US/Japan import standards.

- Efficiency – Increases throughput by 2–3 times compared to manual methods.

- Scalability – Can be integrated with peeling, deveining, freezing, and packaging systems for a full solution.

How It Works

- Shrimp Feeding – Raw shrimp are loaded into the hopper and transferred to the conveyor.

- Alignment & Positioning – The system aligns shrimp in the correct orientation for cutting.

- Deheading Mechanism – Precision blades and rollers remove shrimp heads efficiently with minimal meat loss.

- Waste Collection – Heads are collected separately for disposal or by-product use.

- Cleaning & Discharge – Deheaded shrimp are rinsed and sent to the next process (peeling, freezing, or packaging).

👉 In short, this processing line automatically removes shrimp heads at high speed, preparing them for downstream operations in a continuous workflow.

Machine Parameters

| Specifications | SDL1000A | ||||

| Shrimp spec | From 41/50 to 110/120 | ||||

| Peeling speed | About 1000 kg/hour. Equals to 30-40 labors | ||||

| Water consumption | 750 L/h | ||||

| Greneral power | 13.5 Kw | ||||

| Power suppky | 220v/1Ph/50hz | ||||

| Machine weight | 2500 kg | ||||

| Shrimp Damage Ratio | About 2% | ||||

Key Features

- High Efficiency: Continuous deheading for large volumes of shrimp, reducing labor costs and increasing output.

- Precision Cutting: Ensures minimal meat loss with accurate cutting mechanisms.

- Adjustable for Different Sizes: Compatible with various shrimp sizes through flexible adjustments.

- Food-Grade Materials: Made with stainless steel, easy to clean, and meets hygiene standards.

- Smooth Workflow Integration: Can be combined with peeling, deveining, and packaging equipment for a full processing line.

- User-Friendly Operation: Simple controls with minimal training required for staff.

Competitive Advantage

Compared with manual labor or local machines, Soontrue's shrimp deheading processing line provides:

- Higher Yield – Precision technology reduces shrimp meat loss significantly.

- Faster Output – 2–3x higher capacity than traditional methods.

- Better Hygiene – Stainless steel structure meets HACCP, FDA, and CE standards.

- Lower Labor Dependence – Shrimp processors in Southeast Asia and Latin America have reported saving hundreds of workers per plant.

- End-to-End Integration – Can form part of a complete shrimp processing line including peeling, cooking, and packaging.

Why Choose Soontrue?

With over 30 years of industrial automation experience, Soontrue is a trusted partner for seafood processors worldwide. Our shrimp processing equipment is used by factories in Vietnam, Thailand, India, and Latin America.

- By choosing Soontrue, you gain:

- Proven Experience – Hundreds of successful installations in global shrimp processing hubs.

- Complete Solutions – From deheading machines to full shrimp processing systems.

- Global Support – Overseas engineers, spare parts depots, and 24/7 remote service.

- Reliable ROI – Faster output, reduced costs, and long-term operational stability.

FAQ About Automatic Shrimp Deheading Processing Line

Q1: Can the line handle different shrimp species and sizes?

Yes. It is adjustable for white shrimp, tiger shrimp, and prawns, with quick change settings.

Q2: What is the deheading rate and yield?

The system achieves ≥95% deheading accuracy with high yield and minimal flesh loss.

Q3: How much labor can this save?

One line can replace dozens of workers, reducing labor costs by up to 70%.

Q4: Will deheading damage shrimp meat?

No. Precision cutting ensures minimal damage and better product integrity.

Q5: Can it connect with other shrimp processing machines?

Yes. It integrates smoothly with peeling, deveining, freezing, and packaging equipment.

Q6: How easy is cleaning and maintenance?

The stainless steel design allows quick cleaning, fully compliant with global seafood hygiene standards.

Q7: What’s the typical delivery time?

Normally 60–180 days, depending on capacity and customization.

Q8: What after-sales support is available?

Soontrue provides global installation, training, spare parts supply, and 24/7 technical service.